Synopsis: OEE is the gold standard for measuring manufacturing productivity.

Improving OEE is one of the most important ways to drive operational excellence initiatives for manufacturers.

The big challenges are measuring OEE continuously – at the level of detail required to drive real change, and generating actionable insights in an effective way to drive real-time decision making.

Overall Equipment Effectiveness (OEE) measures how well manufacturing facilities / assets

(machines, workstations, tools) are being used compared to their full potential.

Measuring OEE has been a best practice for manufacturers since the concept was developed by Seiichi Nakajima, a pioneering founder of TPM (Total Productive Maintenance System).

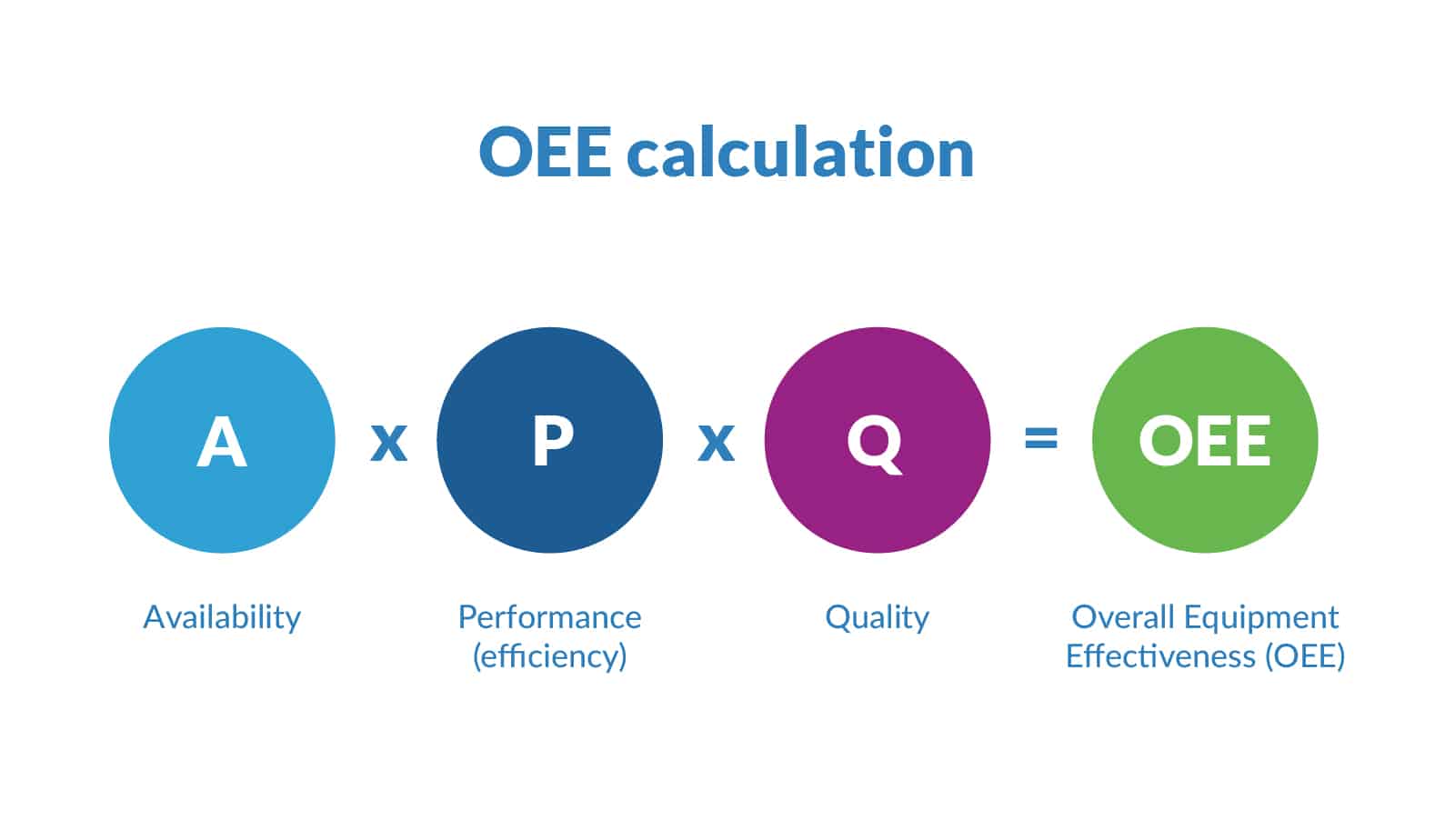

Theoretically, measuring OEE as a KPI is not complicated. Simply compare actual sellable outputs vs. potential outputs (100% quality), at the maximum speed (100% performance), and without interruption (100% availability).

This can be achieved without a major effort to collect and analyze data on the production floor.

So, why are so many manufacturers struggling with this?

Why is it Difficult to Measure and Use OEE?

OEE calculations require measuring and multiplying three metrics: Availability, Performance (efficiency), and Quality.

Within those three factors there are nine influencers which are defined as the “Nine Big Losses”:

Why Connectivity is Key to Measuring OEE Correctly

So back to our challenge for manufacturers. The difficulty isn’t measuring their OEE. It’s in measuring the why behind the number.

Measuring OEE continuously is one of those unique cases where the integration of data from different sources and in different time frames is required. Here’s a simplified diagram of what that could look like:

Ongoing OEE measurement requires connectivity between different management systems (ERP, MES), equipment sets, IoT devices (scales, counters, etc.), and staff reporting (tablets, screens).

Properly managing OEE with rapid setups requires giving context to data

Recent industry changes require manufacturers to be as flexible as possible, and Production lines with only one product are becoming less common than ever.

Different products produced on the same line/machine may be very different in parameters based on material, tools, machine, and environmental conditions.

Availability and Efficiency, two key OEE parameters, must always be put in the context of the specific product and spec, hence managing OEE without knowing what product is being produced at a specific point in time simply doesn’t make sense.

Advanced OEE management tools connect people (operators, technicians, and managers) to IT systems (ERP, APS, PLM) and machine data — ensuring accurate context and proper OEE management.

Connect what’s important

Up-to-date technology enables manufacturers to easily connect older machines and automatically collect as many parameters as needed. By focusing the connectivity efforts on what’s important for OEE management, collecting data automatically, and integrating all necessary data pieces into a coherent informational picture, we can reduce human input to a minimum and focus the team’s attention on event management and decision making.

Conclusion – Effectively Collecting and Integrating Data from Different Sources is a Key Success Factor.

Actively improving OEE with live, actionable insights

Measuring OEE is only the first step. In order to increase OEE, every business problem must be addressed individually. To effectively address problems at each step, actionable alerts must be set up to notify the relevant managers in real-time, so that the problems can be fixed quickly and efficiently.

Advanced IIOT / analytics systems enable manufacturers to make live, dynamic, and proactive decisions based on their existing infrastructure, delivering tangible business results in each step.

Real-time alerts supported by advanced analytics and management tools can generate ‘calls to action’ that will undoubtedly improve productivity.

When you know exactly where the problem lies, the solution is within reach.

Supporting LEAN processes

Implementing FactoryEye is a key success factor and enabler to your Lean Manufacturing program.

All OEE Big Losses may be correlated to several Lean 8 waste model definitions:

Continuously monitoring defects, down-time, inventory, and efficiency are key capabilities that will help spot Non-Added Value waste-related activities and improve the process.

Real-time monitoring does not only create the opportunity to improve but also increases the speed of improvement. Once OEE real-time measurement is designed, we can increase the pace of deployment in order to manage the Define – Measure – Analyze processes, while continuously monitoring OEE and generating live ‘actionable items’ supports the Improve – Control phases, enabling the LSS – Lean Six Sigma DMAIC improvement cycle.

This blog is written by Eli Peleg, Senior Manufacturing Consultant at Magic Software, and Amir Aloni, VP of Manufacturing at Magic Software.