A perennial challenge for the manufacturing sector involves figuring out how to consistently streamline processes and raise productivity. While the industry has readily embraced innovations such as automation and IoT over the years, there remains much more to do for the sector to truly maximise its potential.

Any successful manufacturing firm relies on machinery and the systems that underpin it to get the job done. This includes technologies such as MES, QM, MM or PLM that relate directly to the production floor, but also other legacy systems covering the wider business, such as ERP and CRM. The sector would be nothing without these components, but their existence also creates complexity. As these processes, devices and systems have been introduced iteratively over time, finding a way to integrate all the data they produce and turning this into actionable insight is the next great hurdle for leaders to overcome.

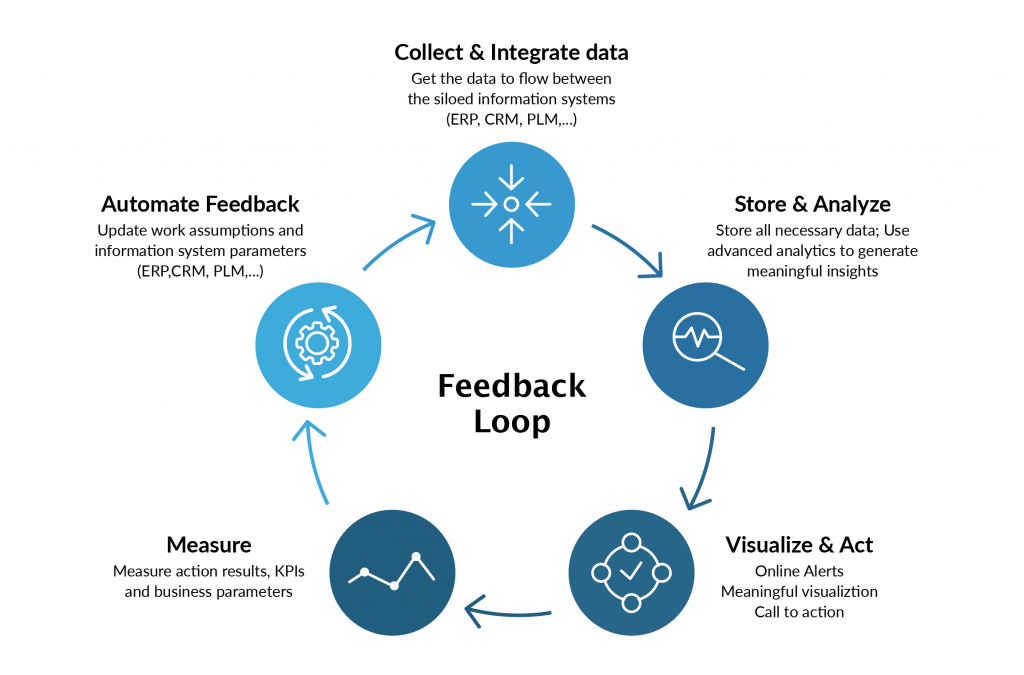

This is where enabling continuous improvement is key. In short, this means consolidating all of this disparate data into a single, closed feedback loop which can be used to consistently inform planning and strategy in both the short and long term.

Think of it this way: production managers and workers can make quick decisions based on data that in the past would have taken hours or even days to acquire. At the same time, leaders also have all the information at their fingertips to make strategic decisions that improve the organisation in the long run. The result is a more productive, efficient and sustainable operation.

For many organisations, true continuous improvement has still not been fully achieved. Below, we examine how it can be done.

Pain points

A major obstacle to implementing continuous improvement is the plethora of siloed data systems that manufacturing firms have in place: ERP, MES, QM, SCM, CRM, IoT device data – the list goes on. Gathering the data from all these sources and making sense of it takes a significant amount of manpower, making it impossible to observe performance in real time. The introduction of emerging technologies such as IIoT, robotics and AI can also complicate matters further, as they deliver new data sources that need to be properly managed.

The result is that manufacturers have little visibility of day-to-day performance on the shop floor. This has a knock-on effect on all aspects of the business, including on-time delivery (OTD), inventory planning and the ability of leaders to make effective operational decisions. The organisation might still be able to function, but it is far from the lean, slick, efficient operation that it could be.

This is where striving to implement and maintain continuous improvement can make all the difference.

Continuous improvement to the rescue

Continuous improvement is one of the core pillars of lean manufacturing, a methodology that emphasises minimising waste while maximising productivity. Becoming a lean organisation has a direct, positive influence on the productivity and efficiency of the business, ultimately contributing to enhanced overall performance.

Below is a short summary of lean manufacturing’s five principles.

- Identify value from the customer’s perspective. Understand the value that customers place on their products and services, and therefore how much the customer is willing to pay. Then eliminate waste in the manufacturing process so that the customer’s price can be met, while achieving maximum profit for the company.

- Map the value stream. Gain a comprehensive understanding of the information and materials required to produce a specific product. This means examining the product’s entire lifecycle, and figuring out how waste can be eliminated at each possible stage.

- Create flow. Ensure all production processes are as efficient as they possibly can be. This requires manufacturers to identify any potential disruptions and introduce integrated processes to prevent them from becoming an issue.

- Establish a pull system. Only start new work when there is demand for it. This is the opposite of a push system, where products are manufactured to meet forecasted demand. These forecasts are often inaccurate, leading to inconsistency in production.

- Pursue perfection through continuous improvement. Constantly strive for perfection in manufacturing processes. This means closely monitoring performance of all equipment and data management systems at all times, enabling rapid identification and remedying of issues.

Effectively, continuous improvement is the final piece of the lean manufacturing puzzle, and ensures the organisation is always on its toes when it comes to streamlining processes, reducing waste and improving productivity.

Making it happen

Continuous improvement is the ideal, but making it a reality is a different challenge entirely. An organisation may have a certain level of understanding of how their systems work and the data they produce, but there is still much more work to do to properly unify this information and get a holistic view of how every system and item of machinery is performing.

Creating the closed feedback loop means incorporating technology that goes beyond the limitations of legacy systems. Continuous improvement cannot be truly embraced if siloed data remains an issue, so any solution that a manufacturer takes on must be able to consistently and reliably integrate every data point into a single dashboard, which leaders can use to conduct analytics, make important decisions and plan more effectively.

Also crucial is the ability to collect data in real time from the production floor, so that operational teams can keep on top of tasks and performance, such as equipment repairs, inventory movement or quality tests. Legacy systems are often unable to provide this level of speed and visibility, so it is important that leaders adopt new technologies that are able to deliver it.

A bright new era for manufacturing

Reaching the holy grail of continuous improvement takes a lot of work, but with the right approach, the task is by no means insurmountable. Visualising the closed feedback loop is a good way to understand what needs to be done: once you get a grasp of all of your disparate systems and how to integrate them, the lean manufacturing dream will become a reality.

So what can you do now?

To begin with, Magic’s FactoryEye can help you gain control of your business performance by fully integrating information flow from order to delivery, by seamlessly connecting your existing ERP, CRM, PLM, WMS, data hub and production floor.

Magic’s FactoryEye helps unleash real-time information from your existing systems, by using FactoryEye’s low code ‘plug-and play’ integration tool and smart dashboards.

Collaboratively identify opportunities to semi-automatically correct issues, predict potential stoppages, and make continuous improvements.From shop floor to top floor, Magic’s FactoryEye helps you focus on KPIs that optimize your business performance over time.

Contact our team today to see how we can support your transition to Industry 4.0.